Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

Bridge icing is one of the major hidden dangers to traffic safety in winter. Icing not only reduces the friction coefficient of the road surface, increasing the risk of vehicle skidding and accidents, but may also cause damage to the bridge structure. Traditional icing monitoring mainly relies on manual inspections, which has problems such as low efficiency, high cost, and poor real - time performance. Therefore, establishing an efficient and accurate online bridge icing monitoring system is of great significance for ensuring traffic safety and the health of bridge structures.

An online bridge icing monitoring system that is real - time and accurate is constructed by using Internet of Things technology, sensor technology, and data analysis technology. The system can monitor key parameters such as the surface temperature, humidity, and icing status of the bridge in real - time, and provide scientific decision - making support for traffic management departments through data analysis and early - warning functions.

System Composition

Sensor Module

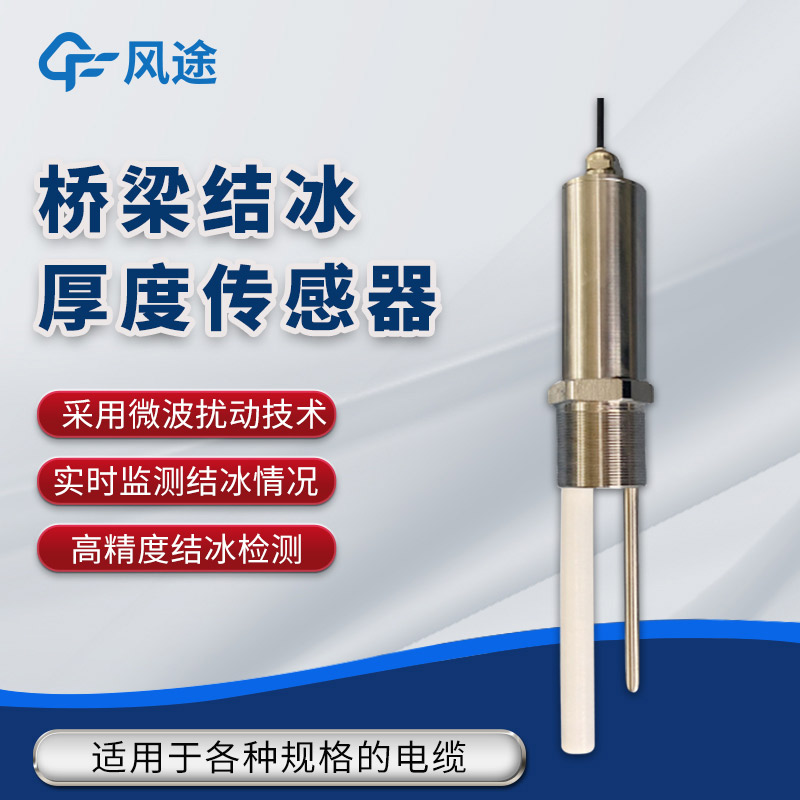

The Ice thickness sensor is a high - precision monitoring device based on microwave perturbation technology and is widely used in scenarios such as wind turbine blades, outdoor cables, and communication antennas. Its core principle is to monitor the icing information in sensitive areas in real - time and calculate the ice thickness through the feedback differences of microwave signals for different substances such as ice, water, and air. The sensor supports the icing alarm function and can activate the de - icing system according to preset thresholds, effectively reducing the risk of ice - related accidents.

The FT - JB1 has characteristics such as high precision, easy installation, and real - time monitoring. Its icing detection range is 0.5mm - 50mm, the resolution is 0.1mm, the operating temperature range is - 40℃ - 85℃, and the protection level reaches IP67, adapting to harsh environments. The sensor uses the RS485 communication method and supports the Modbus - RTU protocol, which is convenient for integration into large - scale monitoring systems.

Data Collection and Transmission Section

Data collection unit: It undertakes the key task of collecting various sensor data in real - time to ensure the timely collection of monitoring data.

Data transmission unit: By means of wired connections or wireless communication, the collected data is stably and accurately transmitted to the control center to achieve remote data transmission.

Data Analysis and Processing Part

Data processing program: It deeply analyzes the obtained data and accurately judges the icing risk level of the bridge.

Early - warning system: According to the final results of data analysis, it can automatically trigger early - warning signals and prompt relevant personnel in a timely manner.

User Interaction Interface Level

Monitoring platform: It visually presents real - time monitoring data for users and supports the convenient query of historical data for data backtracking.

Mobile application: It enables managers to view the actual status of the bridge anytime and anywhere, breaking through time and space limitations.

De - icing System Section

Automatic de - icing equipment: Such as heating devices or automatic de - icing agent spraying equipment. Once icing is detected, it can automatically start the de - icing operation to ensure the safety of the bridge.